Babban Ingancin Tapered abin nadi mai ɗauke da jerin 32000

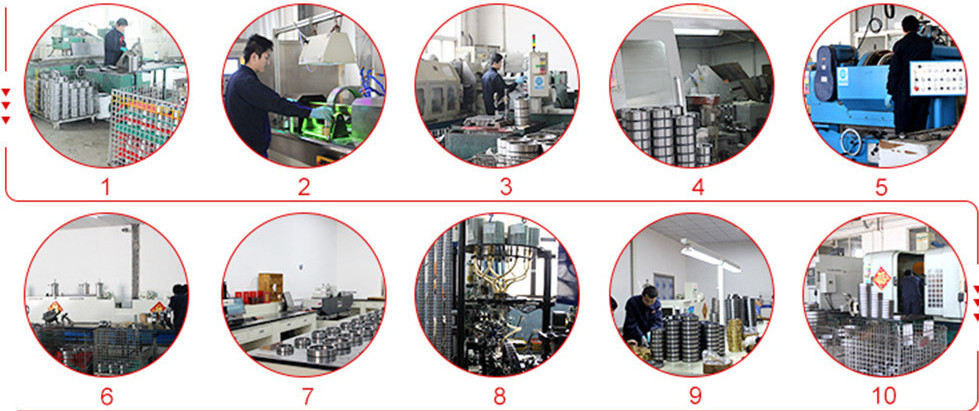

Tsarin samarwa

Muna da cikakken layin samar da niƙa ta atomatik da layin taro tare da cikakken kayan gwaji na atomatik wanda ke sa ingancin bearings daidai yake.Mun sanya bearings 100% gwada.

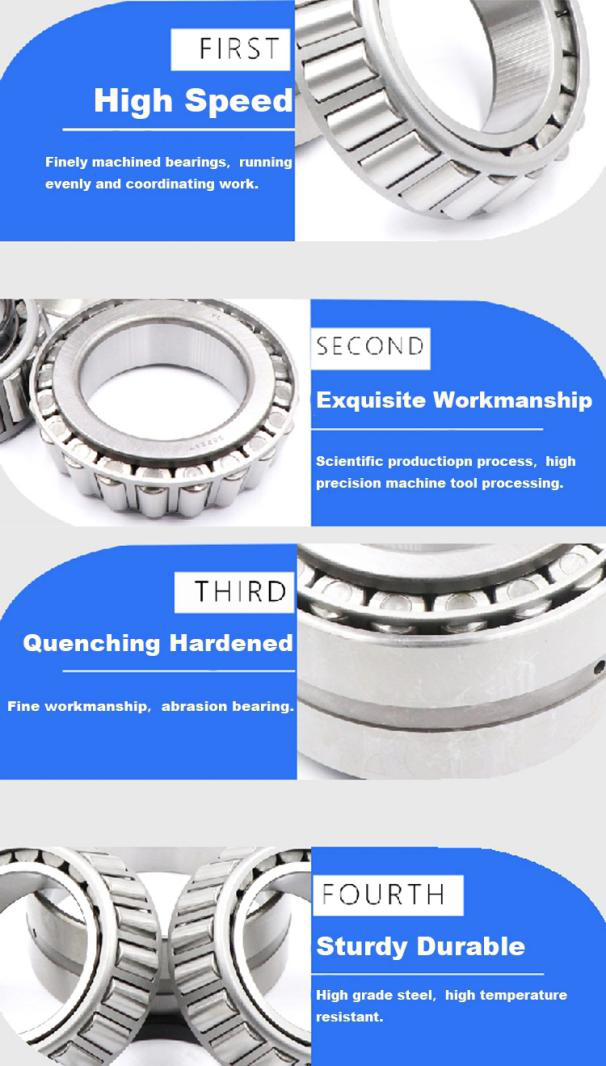

Amfanin samfur

Siffar geometric na abin nadi da aka ɗora yana ba da damar abin nadi tsakanin hanyoyin tsere, wanda ke nufin cewa abin nadi ba zai yiwu ya zame ko zamewa ba lokacin da aka sauke abin nadi.Sauran nadi bearings suna da ƙananan buƙatun kaya don tabbatar da cewa abin nadi ba ya zamewa tsakanin nadi da titin tsere.Guguwa ko zamewa yana da illa saboda yana share man shafawa daga sama, wanda zai haifar da lalacewa da gazawar da wuri.

Gidan ajiyar mu

Nau'in jigilar kaya

Mun yi haɗin gwiwa tare da ƙwararrun masu jigilar kayayyaki na shekaru masu yawa, suna shirya jigilar kaya.Komai ta hanyar bayyana, ta iska ko ta ruwa, za mu bi diddigin yadda kayayyaki ke tafiya, don tabbatar da cewa kaya sun zo muku a kan lokaci kuma cikin yanayi mai kyau.

Aikace-aikacen samarwa

Ana amfani da samfuranmu a fannonin masana'antu, kamar kayan aikin siminti, na'urorin hakar ma'adinai, kayan aikin niƙa, kayan aikin wutar lantarki, kayan aikin takarda, kayan aikin filin mai, kayan ƙarfe, da sauransu.Tapered abin nadi hali shine amfaninmu.

Siga

| GIRMA | Girma | Mahimman ƙididdiga masu nauyi | Nauyi | |||||||

| m | a tsaye | |||||||||

| d | D | B | C | T | Rmin | rmin | KN | KN | kg | |

| 32004X | 20 | 42 | 15 | 12 | 15 | 0.6 | 0.6 | 25.1 | 28.2 | 0.095 |

| 32005X | 25 | 47 | 15 | 11.5 | 15 | 0.6 | 0.6 | 28.0 | 34.1 | 0.112 |

| 32006X | 30 | 55 | 17 | 13 | 17 | 1 | 1 | 35.7 | 46.8 | 0.17 |

| 32007X | 35 | 62 | 18 | 14 | 18 | 1 | 1 | 43.2 | 59.2 | 0.224 |

| 32008X | 40 | 68 | 19 | 14.5 | 19 | 1 | 1 | 51.9 | 71.1 | 0.269 |

| 32009 | 45 | 75 | 20 | 15.5 | 20 | 1 | 1 | 58.4 | 81.4 | 0.337 |

| 32010X | 50 | 80 | 20 | 15.5 | 20 | 1 | 1 | 61.1 | 89.0 | 0.366 |

| 32011 | 55 | 90 | 23 | 17.5 | 23 | 1.5 | 1.5 | 80.2 | 117.2 | 0.551 |

| 32012 | 60 | 95 | 23 | 17.5 | 23 | 1.5 | 1.5 | 81.7 | 122.2 | 0.584 |

| 32013 | 65 | 100 | 23 | 17.5 | 23 | 1.5 | 1.5 | 82.8 | 127.3 | 0.620 |

| 32014 | 70 | 110 | 25 | 19 | 25 | 1.5 | 1.5 | 104.3 | 160.1 | 0.839 |

| 32015 | 75 | 115 | 25 | 19 | 25 | 1.5 | 1.5 | 103.1 | 160.2 | 0.875 |

| 32016 | 80 | 125 | 29 | 22 | 29 | 2 | 1.5 | 140 | 220 | 1.27 |

| 32017 | 85 | 130 | 29 | 22 | 29 | 2 | 1.5 | 140 | 220 | 1.32 |

| 32018 | 90 | 140 | 32 | 24 | 32 | 2 | 1.5 | 170 | 270 | 1.72 |

| 32019 | 95 | 145 | 32 | 24 | 32 | 2 | 1.5 | 185.0 | 280 | 1.84 |

| 32020 | 100 | 150 | 32 | 24 | 32 | 2 | 1.5 | 192 | 282 | 1.85 |

| 32021 | 105 | 160 | 35 | 26 | 35 | 2.5 | 2 | 205.0 | 335 | 2.4 |

| 32022 | 110 | 170 | 38 | 29 | 38 | 2.5 | 2 | 245 | 402 | 3.02 |

| 32024 | 120 | 180 | 38 | 29 | 38 | 2.5 | 2 | 242.0 | 405 | 3.18 |

| 32026 | 130 | 200 | 45 | 34 | 45 | 3 | 2.5 | 335 | 568 | 4.94 |

| 32028 | 140 | 210 | 45 | 34 | 45 | 3 | 2.5 | 330.0 | 568 | 5.15 |

| 32030 | 150 | 225 | 48.5 | 36 | 48.5 | 3 | 2.5 | 368 | 635 | 6.25 |