Don bearings tare da ƙwanƙwasa ƙwanƙwasa, zoben ciki koyaushe ana shigar da shi tare da tsangwama.Ba kamar silinda ba, tsoma bakin bearings ɗin da aka ɗora ba a ƙayyade shi ta hanyar juriyar da aka zaɓa ta dace ba, amma ta nisan ci gaba na ɗaukar hoto a kan jaridar da aka buga, bushing ko janye hannun riga.Ƙimar radial na ciki na ƙugiya yana raguwa yayin da mai ɗaukar hoto ya ci gaba a kan jaridar da aka buga.Ta hanyar auna raguwa, za ku iya ƙayyade matakin tsangwama da tsangwama na dacewa.

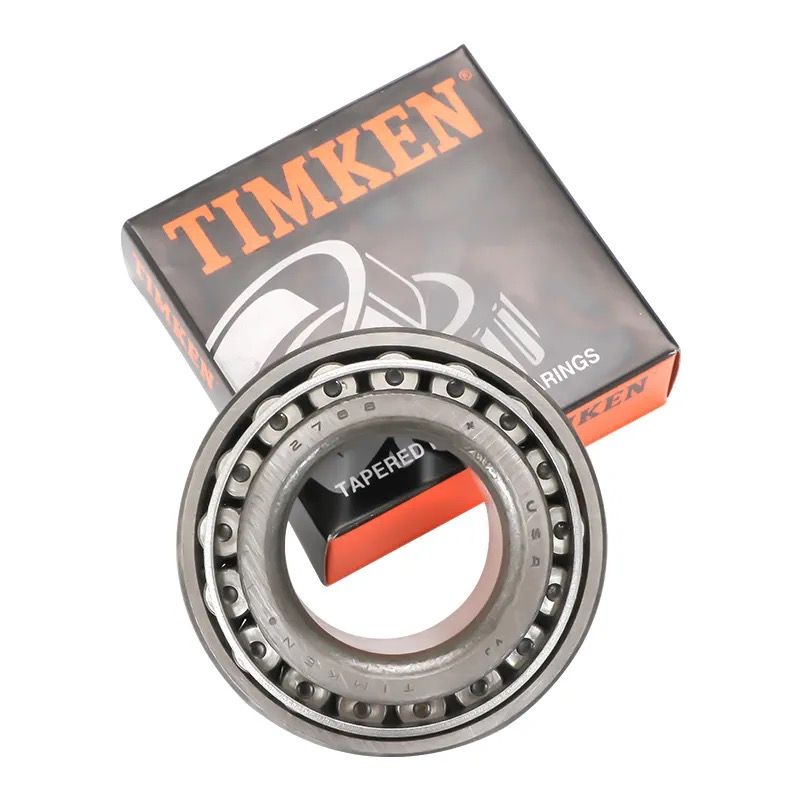

Lokacin shigar da bearings ball bearings, CARB toroidal roller bearings, spherical roller timken bearings da high-madaidaicin cylindrical roller bearings tare da tapered bores, ƙayyade ƙimar raguwar radial na ciki ko madaidaicin axial akan madaidaicin tushe.Nisan ci gaba, a matsayin ma'aunin tsangwama.Ana samun ƙimar jagora don raguwar sharewa da nisan gaba axial a cikin sassan samfurin da suka dace.

Ƙananan bearings

Ƙananan bearings na iya amfani da ƙwaya don tura su cikin gindin da aka zana.Inda ake amfani da bushings, ana amfani da goro na hannu.Za'a iya tura ƙaramin hannun rigar cirewa zuwa cikin rami mai ɗauka tare da goro.Ana iya ƙara goro tare da maƙallan ƙugiya ko maƙallan huhu.Kafin fara shigarwa, ya kamata a ƙara man kadan a saman jarida da hannun riga.

Manya da matsakaici bearings

Ƙarfin hawan da ake buƙata don manyan ɓangarorin timken yana ƙaruwa sosai kuma yakamata a yi amfani da kwayoyi na hydraulic da/ko hanyoyin allurar mai.

Dukansu hanyoyin da ke sama suna iya sauƙaƙe tsarin shigarwa.Ana samun kayan aikin mai da ake buƙata don sarrafa kwaya mai ƙarfi da amfani da hanyar mai.Ana iya samun cikakkun bayanai game da waɗannan samfuran a cikin sassan da suka dace na kasida ta kan layi "Kayayyakin Kulawa da Lubrication".

Lokacin amfani da na'ura mai ba da hanya tsakanin hanyoyin sadarwa don shigar da ma'auni, dole ne a sanya shi a kan ɓangaren zaren jarida ko zaren hannun riga don piston annular ya kasance kusa da zoben ciki na bearing, goro a kan shaft ko riƙewa. zobe shigar a kan shaft karshen.Ana tilasta mai a cikin kwaya mai ƙarfi ta hanyar famfo mai, yana motsa piston a cikin jagorar axial tare da ƙarfin da ake buƙata don aminci da ingantaccen shigarwa.Amfani da na'ura mai aiki da karfin ruwa, shigar da abin nadi mai siffar zobe zuwa

Yin amfani da hanyar allurar mai, ana yin allurar mai tsakanin Timken bearing da jarida a ƙarƙashin matsin lamba don ƙirƙirar fim ɗin mai.Wannan fim din mai yana raba abubuwan da ke tattare da jima'i kuma yana rage girman rikici tsakanin abubuwan da suka dace.Ana amfani da wannan hanyar gabaɗaya lokacin shigar da bearings kai tsaye a kan mujallun da aka ɗora, amma kuma ana amfani da ita don shigar da bearings a hannun adaftar da hannayen riga da aka shirya musamman don hanyar allurar mai.Famfutar mai ko injector mai yana haifar da matsi mai mahimmanci don allurar mai tsakanin abubuwan da suka dace ta hanyar ragi da tashoshi na rarraba mai akan shaft ko hannun riga.Lokacin zayyana shimfidar ɗabi'a, dole ne a ba da la'akari don tsara ramukan da ake buƙata da tashoshi akan shaft.An shigar da abin nadi mai siffar zobe a hannun rigar cirewa tare da tsagi mai.Ta hanyar allura mai a saman ma'auratan da kuma ƙarfafa sukurori a jere, ana danna hannun cirewa a cikin rami mai ɗaukar hoto.

Lokacin aikawa: Satumba-28-2023